1. Aging of the Laser Diode

Every optical module contains a laser diode that emits light into the fiber. Over time, this laser loses power due to natural wear of the laser medium. This results in a weaker transmitted signal, which can lead to:

- Higher bit error rates

- Unstable connections

- Warnings like “optical Tx power low”

Using Digital Diagnostics Monitoring (DDM), you can read the transmit power (TX power). A gradual decline over months or years is a clear sign of aging [1].

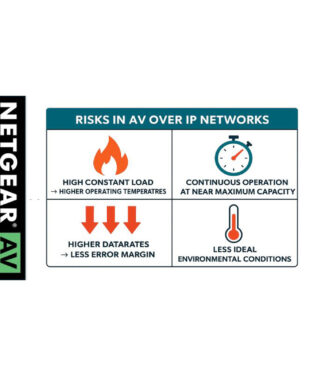

2. Thermal Stress: Heat as an Accelerating Factor

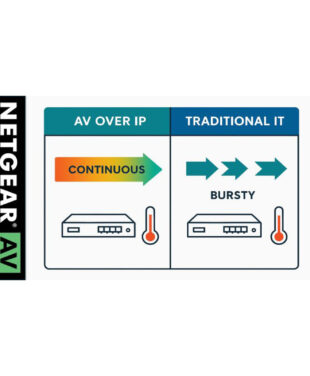

Heat is the biggest enemy of electronics. In AV over IP networks, modules often run continuously at high speeds, leading to:

- Higher operating temperatures

- Accelerated degradation of the laser and photodiode

- Soldering faults due to thermal cycles

According to the Arrhenius effect, every 10°C increase in temperature halves the lifespan of components. A module consistently operating at 85°C may fail up to five times faster than one at 40°C.

3. Duty Cycle and Intensive Use

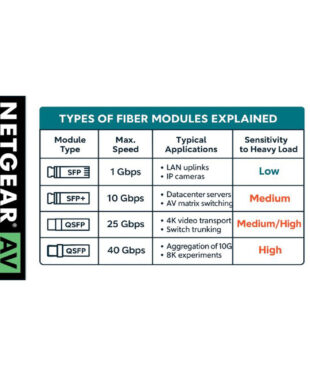

Although a fiber laser always emits light as long as the link is active, intensive use does make a difference. At higher data rates (10G, 25G, 100G), components must work harder:

- More heat generation

- Less tolerance for degradation

- Faster impact from minor defects

A module transporting a 4K video stream 24/7 is under much heavier load than one that occasionally transfers a file.

4. Environmental Factors: Dirt, Moisture, and Mechanical Wear

External factors also play a role:

- Dust and dirt on connectors dampen the signal and increase the load on the laser

- Moisture and corrosion can damage connectors

- Frequent plugging and unplugging wears down contact pins

- ESD (Electrostatic Discharge) can damage sensitive components

A dirty connector can even cause microscopic sparks that damage the fiber module.

5. Symptoms of Wear

Wear often manifests subtly:

- A stable link suddenly becomes unstable

- Error counters increase without a clear cause

- DDM values fall outside normal margins

In severe cases, you may see a TX power of -20 dBm or lower—a sign that the laser is nearly “burned out.”

6. Quality Makes the Difference

Not all modules are created equal. OEM modules and high-quality third-party transceivers use better lasers that last for years. Budget modules, on the other hand, may show signs of degradation after just one year of continuous use.

Conclusion

Fiber modules wear out—slowly but surely. In AV over IP networks, where the load is high and constant, these wear processes can become visible more quickly. By understanding how modules degrade, we can better anticipate issues and take preventive action.

In the next blog, we’ll explore the specific risks AV over IP poses to the lifespan of fiber modules.

More information

Visit our website to see the AV Solutions.

Discover everything you need to know about AVoIP and building an AV network.

Get free support for your AV project from our senior AV engineers.