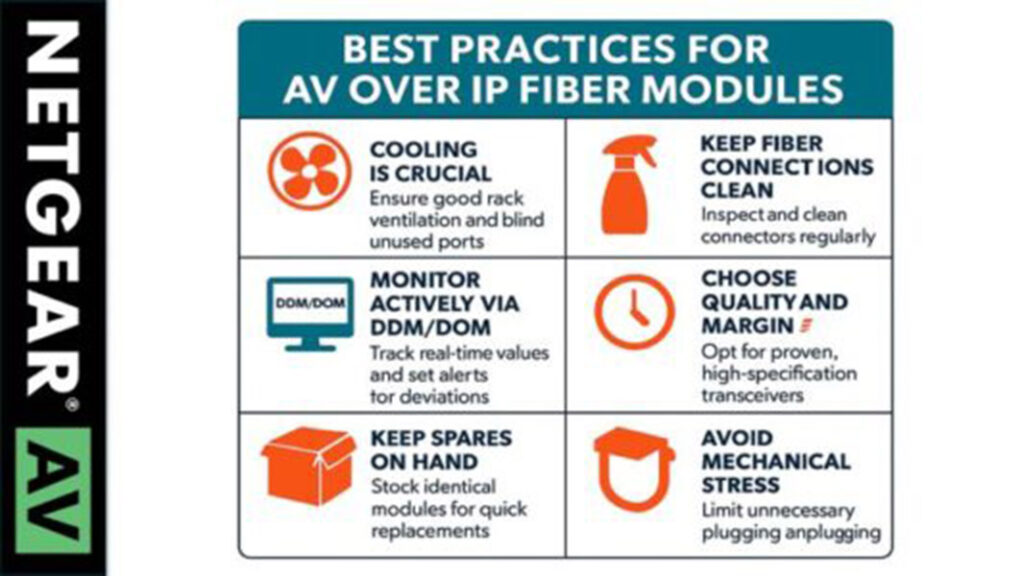

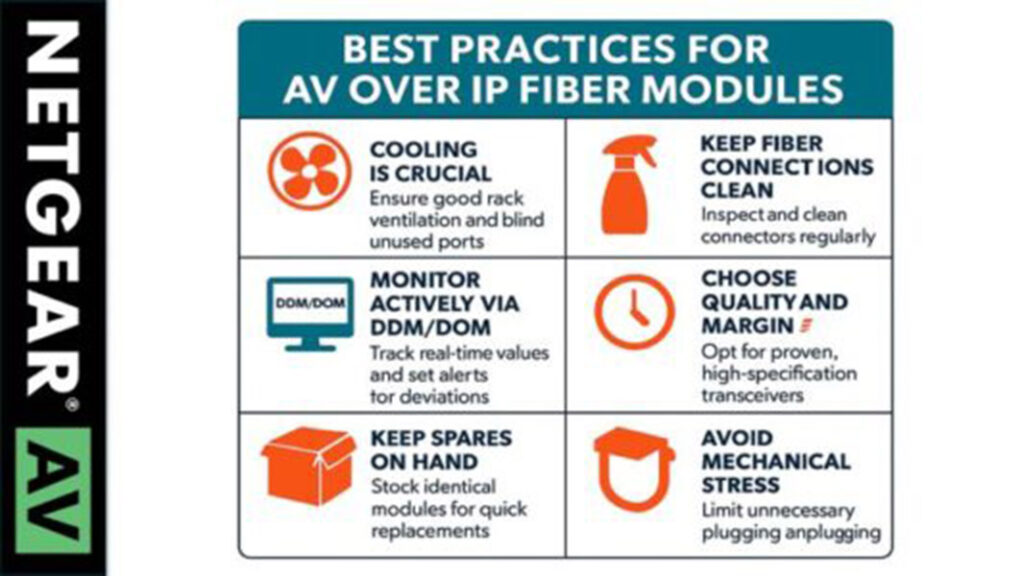

Cooling Is Crucial

- Ensure proper ventilation in racks and switches

- Use blanking panels on unused ports

- Consider industrial-grade modules for high ambient temperatures

- Monitor temperature via DDM/DOM and intervene when thresholds are exceeded

Heat is the most significant accelerating factor of wear.

Keep Fiber Connections Clean

- Clean connectors regularly with appropriate tools

- Use dust caps on unused ports and cables

- Check for contamination during every (re)connection

Dirt increases optical attenuation and can even cause damage.

Actively Monitor via DDM/DOM

- Track real-time values: temperature, TX/RX power, bias current

- Set alerts for anomalies

- Analyze error messages and logs

Early signs of degradation are often visible before failure.

Plan Replacement and Document

- Develop a replacement strategy (time, usage, performance)

- Record installation dates and locations for each module

- Rotate modules between critical and less critical positions

Preventive replacement avoids downtime during crucial moments [1].

Choose Quality and Headroom

- Use NETGEAR-quality or well-tested third-party modules

- Avoid budget modules on critical links

- Select modules that outperform the bare minimum requirements

Extra headroom provides a buffer against natural wear.

Keep Spare Parts on Hand

- Stock identical modules during installation

- Use them for quick replacements or testing

- Ensure compatibility and pre-test them

A good inventory prevents stress during unexpected failures.

Beware of Mechanical Stress

- Limit unnecessary plugging and unplugging

- Use patch panels to relieve strain on modules

- Respect the specified lifespan of connectors

Mechanical wear is an underestimated cause of failures.

Conclusion

Fiber-optic modules are robust, but not indestructible. In AV over IP networks, they are heavily stressed, often under challenging conditions. By making informed choices, monitoring diligently, and managing smartly, you can significantly extend their lifespan—and keep your network reliable.

With this blog series, I hope to help AV professionals future-proof their fiber installations. Do you have questions, real-world experiences, or additional tips? Let me know—I’d love to keep the conversation going.